Jigs and fixtures for manufacture, components for assembly line equipment, working mechanical prototypes, and batches of custom-designed replacement parts can all be printed in-house, saving you thousands of dollars and days or even weeks of time compared to conventional manufacturing. This is 3D printing used in industry.

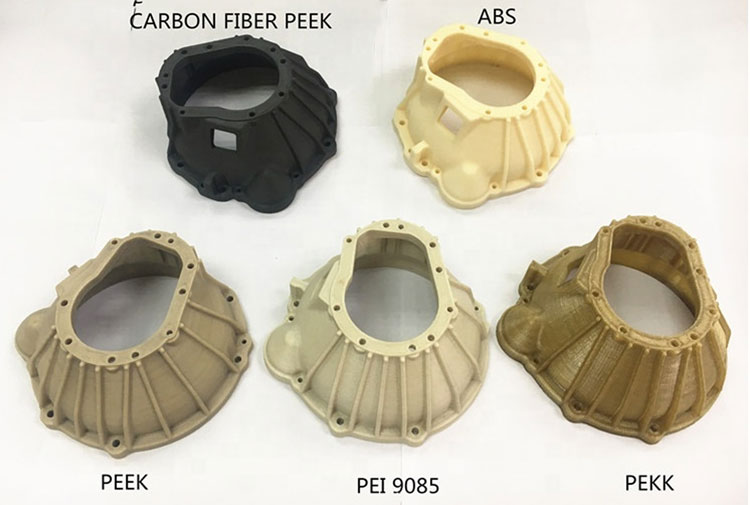

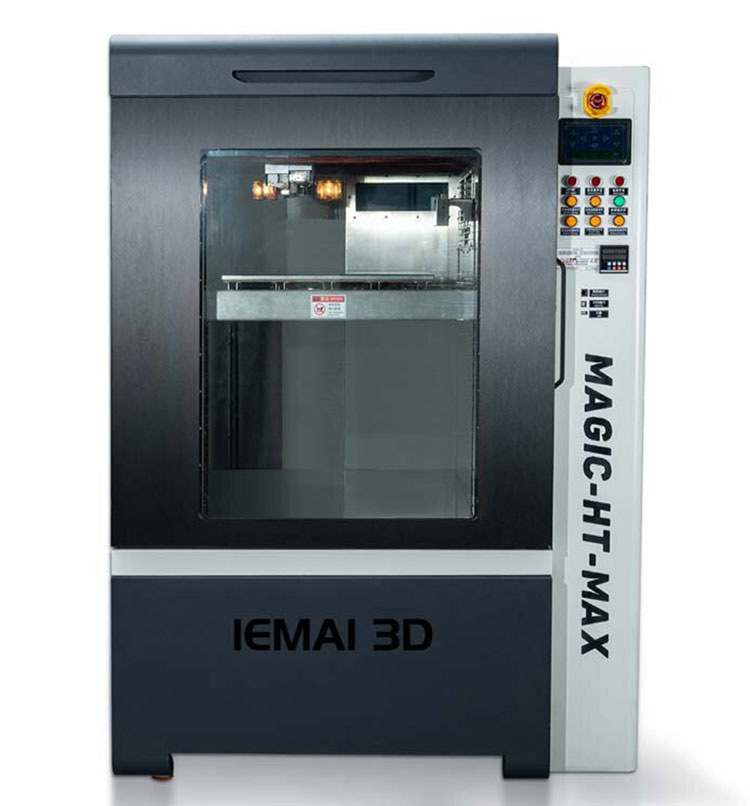

IEMAI 3D Industrial printers are now becoming commonplace in heavy industry, aircraft, healthcare, and automakers and manufacturers because they have long since passed the durability, repeatability, and reliability tests. Machine shops and metal fabrication are being replaced by these machines, which produce custom, unique parts on demand in engineering polymers that are lightweight and durable.

IEMAI 3D Industrial FDM printers are built to be dependable and repeatable. They have more precise control over the printing’s processing parameters to make sure of this.

Furthermore think about whether you require a machine that is approved for use in a controlled medical environment, one that filters out potentially harmful chemical emissions from the printing process, one that fits through a conventional doorframe, or one that includes staff training and ongoing support. Furthermore take into account the amount of time a print requires to cool before printing can start, as well as post-processing and finishing, as these might effect your shop’s overall productivity.