In October 2024, IEMAI 3D launched high-performance 3D printing PEKK filaments based on Arkema’s Kepstan® PEKK, which is now available to users on their platform. The 3D-printed parts with PEKK provide better dimensional stability and high Z-axis strength as compared to PEI or PEEK filaments.

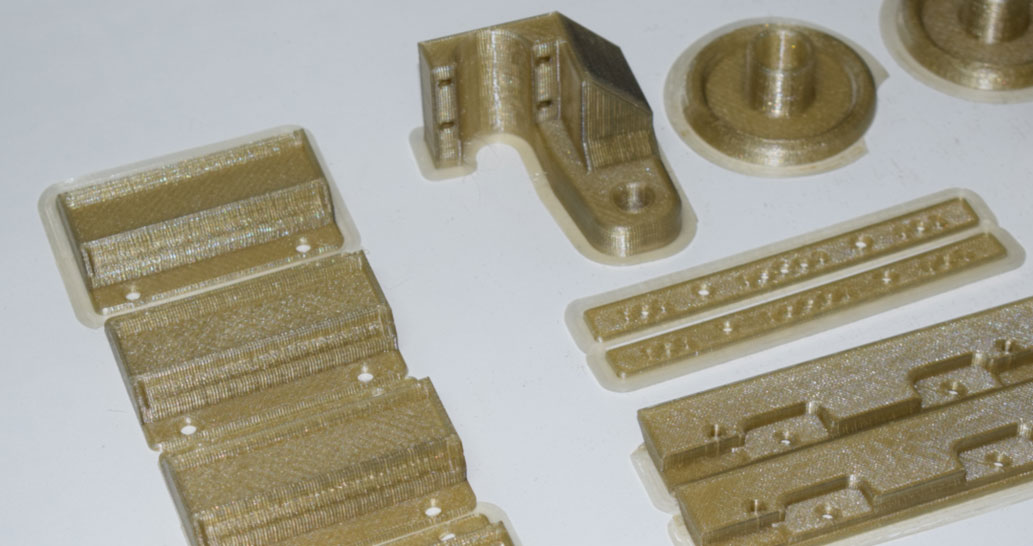

Kepstan ® PEKK material printed parts

Mr. Pierre Gonnetan, Global 3D Printing Market Manager for Arkema’s High Performance Polymers Division, stated, “We are thrilled at Arkema to see our Kepstan ® PEKK material being recognized for its outstanding performance in FDM 3D printing technology. Kepstan® PEKK offers exceptional ease of processing and superior mechanical and fire properties, making it an ideal material choice for a wide range of high-performance applications, from aerospace to industrial challenging use cases. We are committed to continuing our innovation in advanced materials to support the evolving needs of the 3D printing industry.

Mr. Allen Jiang, General Manager of IEMAI, stated, “We are excited to announce that Arkema’s high performance Kepstan® PEKK is now available on IEMAI 3D platform to address the key material challenges such as weak longitudinal mechanical properties in 3D printed parts, a long-standing issue in FDM technology.”

Kepstan ® PEKK material in printing process

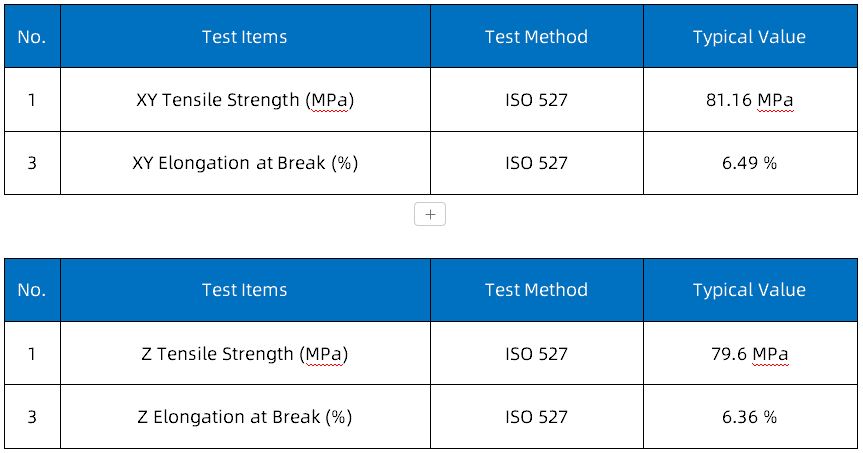

Using IEMAI3D high-temperature series 3D printer for Arkema Kepstan® PEKK underwent compatibility testing and obtained excellent performance reports and user experience. This material exhibits excellent printability and dimensional stability during printing. The slower crystallization enhances interlayer adhesion during printing and results in higher Z-axis performance of printed parts, as illustrated below.

Tensile properties table

In addition, due to the high temperature resistance and mechanical performance requirements of IEMAI3D new equipment, after testing, IEMAI3D used the PEKK material to make tooling fixtures and prototypes for its new equipment to improve the efficiency of R&D iterations and reduce processing costs.

Some applications of the printed parts

Kepstan ® PEKK It is a registered trademark of Arkema.

Building on its unique set of expertise in materials science, Arkema offers a portfolio of first-class technologies to address ever-growing demand for new and sustainable materials. With the ambition to become in 2024 a pure player in Specialty Materials, the Group is structured into 3 complementary, resilient and highly innovative segments dedicated to Specialty Materials – Adhesive Solutions, Advanced Materials, and Coating Solutions – accounting for some 92% of Group sales in 2023, and a well-positioned and competitive Intermediates segment. Arkema offers cutting-edge technological solutions to meet the challenges of, among other things, new energies, access to water, recycling, urbanization and mobility, and fosters a permanent dialogue with all its stakeholders. The Group reported sales of around € 9.5 billion in 2023, and operates in some 55 countries with 21,100 employees worldwide. (Website: www.arkema.com)

IEMAI 3D is a global industrial grade 3D printer brand, committed to provide users with the “All in one” 3D printing solution of multi material compatible issue. IEMAI 3D supports most of the thermoplastic materials in the 3D printing markets and assist the user to resolve the issue encounter during manufacturing, and all 3D printers and materials have achieved CE and ROHS certification. We attach great importance to brand building and have obtained trademarks certificates from China, United Sates and the European Union. We pursue core technology research and development, and have obtained software copyrights, invention patents, utility model patents, appearance design patents, and the title of national high-tech enterprise. At present, our 3D printing solutions have been applied to aerospace, automotive, petrochemical, medical and electronics manufacturing. (Website: www.iemai3d.com/)