The field of robotics is undergoing innovation and transformation at an unprecedented pace. Among them, the selection of materials and the innovation of production methods have become key forces driving progress in this field. The application heat of PEEK material in the field of robotics continues to rise, and 3D printing technology has also brought a new flexible production mode for robot production.

Replacing Steel with Plastic, the ‘Ideal Choice’ for Robots

PEEK (polyetheretherketone) is a high-performance thermoplastic engineering plastic. It has a series of characteristics that can replace steel with plastic, ensuring excellent performance while having much lower density than metal, making it show great potential for application in the field of robotics.

Firstly, PEEK material has excellent mechanical properties and can withstand large external forces without deformation, which is crucial for robots to perform tasks in complex environments. For example, in the joint parts of industrial robots, materials need to be able to withstand frequent movements and large loads. The high-strength characteristics of PEEK material can ensure the stability and durability of joints, reduce failures caused by material fatigue, and extend the service life of robots.

Secondly, PEEK material has good chemical stability. It can resist the erosion of various chemicals and maintain stable performance whether in humid environments or in contact with corrosive liquids. This feature enables robots to operate safely and reliably in special industries such as chemical and food processing, without being affected by chemical substances in the environment that affect their performance.

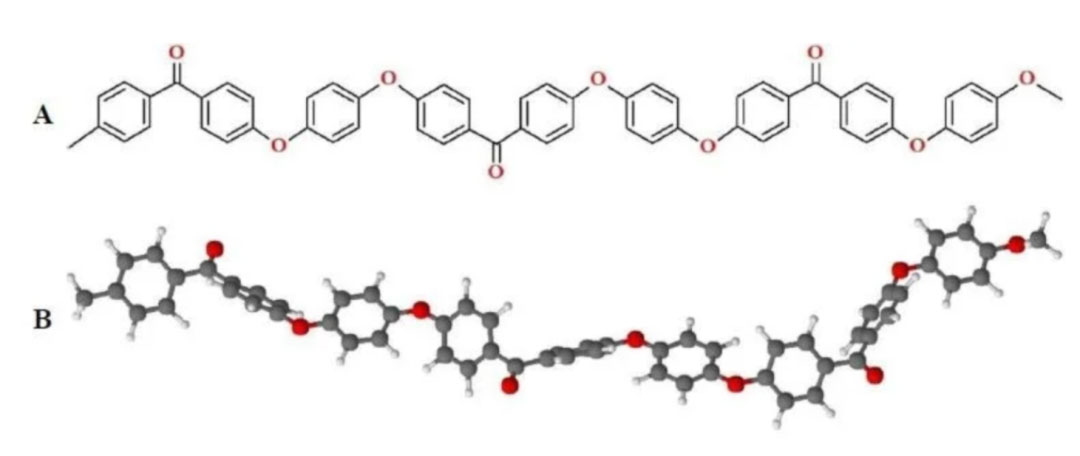

Molecular structure of PEEK material

In addition, PEEK material also has excellent high temperature resistance. It can maintain good physical and mechanical properties at high temperatures, which is undoubtedly an ideal material choice for robots working in high-temperature environments, such as welding robots, high-temperature furnace operation robots, etc.

3D Printing: Ushering in a New Era of Flexible Robot Production

Traditional robot production methods often require a large number of molds and complex processing techniques, which are not only costly but also have long production cycles, making it difficult to meet rapidly changing market demands. 3D printing technology may bring revolutionary changes to robot production.

In the stage of robot development, 3D printing technology can quickly produce prototypes, help engineers verify design ideas, and promptly identify and solve problems. Compared with traditional prototyping methods, 3D printing greatly shortens the research and development cycle and reduces research and development costs. Moreover, engineers can quickly modify and optimize the model based on test results, and then print it again. This iterative design process can accelerate the development process of robots.

IEMAI3D printing PEEK material robot components (before assembly)

IEMAI3D printing PEEK material robot components (after assembly)

In the production stage, 3D printing can achieve personalized customized production. Different customers may have different requirements for the functions and performance of robots, and traditional mass production is difficult to meet this personalized demand. 3D printing technology can quickly print robot components that meet specific customer requirements, and even directly print complete robots. This personalized customized production model can not only improve customer satisfaction, but also open up broader market space for enterprises.

In the Field of Robotics, PEEK and 3D Printing will be Perfectly Combined

At present, there have been many successful cases of using PEEK materials in the field of robotics. For example, Tesla’s humanoid robot Optimus and some key components of medical robots are made of PEEK material, which not only meets the strict requirements of medical environments for materials, but also achieves personalized customization, improving the therapeutic effect of medical robots.

The excellent performance of PEEK material also endows 3D printed robot components with higher quality. PEEK material components made using 3D printing technology not only have excellent mechanical properties and chemical stability, but also demonstrate outstanding lightweight performance. Lightweight is crucial for robots as it can reduce their energy consumption, improve their movement speed and flexibility.

IEMAI3D high performance printing solution

IEMAI3D printing PEEK material robot case

Dongguan Imai Intelligent Technology Co., Ltd is a high-tech enterprise in China focusing on 3D printing R&D and production. Its brand IEMAI 3D is a global industrial grade 3D printer brand, committed to provide users with the “All-in-one” 3D printing solution of multi material compatible issue. IEMAI 3D supports most of the thermoplastic materials in the 3D printing markets and assist the user to resolve the issue encounter during manufacturing, and all 3D printers and materials have achieved CE AND ROHS certification. We attach great importance to brand building and have obtained trademarks certificates from China, United States and the European Union. We pursue core technology research and development, and have obtained software copyrights, invention patents, utility model patents, appearance design patents, and the title of national high-tech enterprise. At present, our 3D printing solutions have been applied to aerospace, automotive, petrochemical, medical and electronics manufacturing.