Preface: On November 22, 2024, the Formnext exhibition in Germany successfully conducted. The scale of exhibitors and visitors at this exhibition exceeded historical record. 3D printing technology is gradually being applied in various industries, and there is a trend towards more diversity and segmentation in equipment, materials, processes, and software. Users have raised more professional application needs.

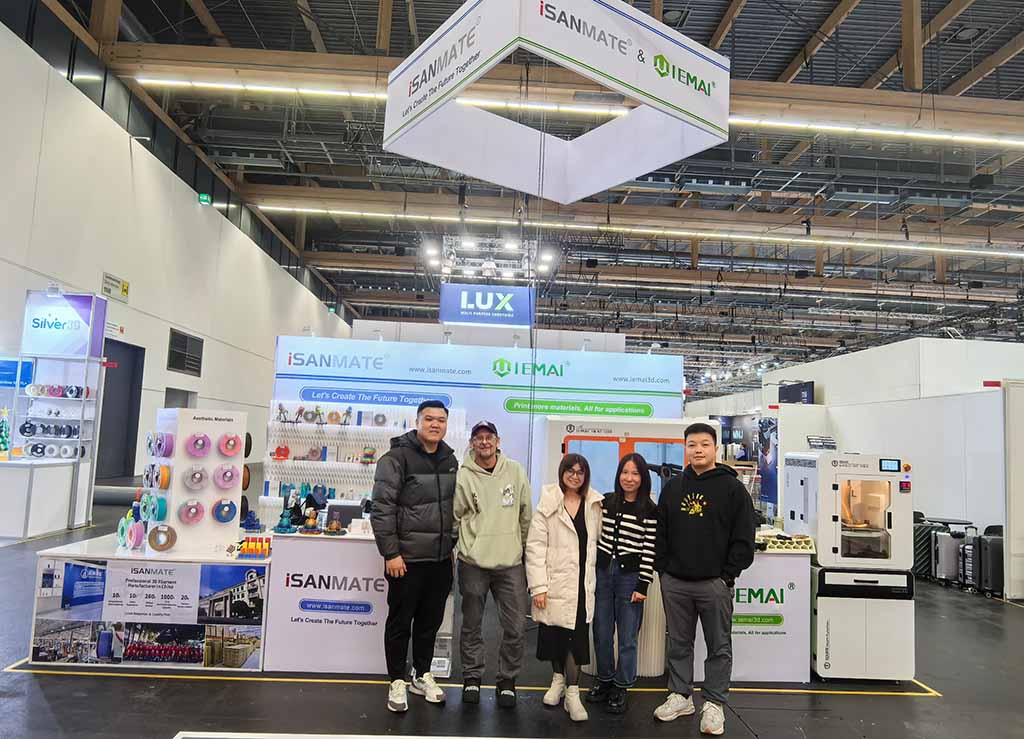

IEMAI at Formnext site

01 Ultra large pellet 3D printing is rapidly developing in the European and American markets

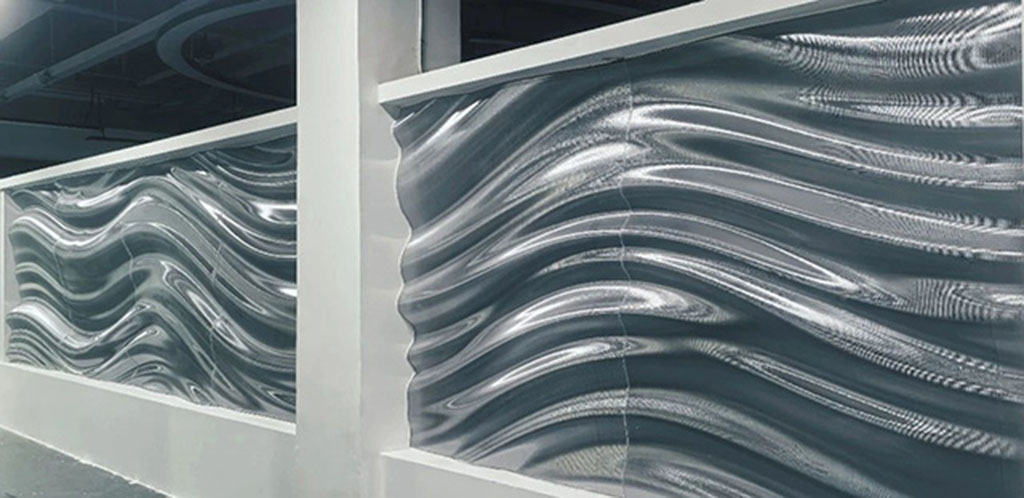

At the Formenxt exhibition in Germany and the Rapid tct exhibition in North America in 2024, it can be seen that ultra large plastic pellet printing is becoming a mainstream trend in Europe and America. Many foreign brands have launched ultra large gantry structures and multi axis pellet printing solutions based on robotic arms. Material manufacturers are actively arranging raw material modification and supply. Some excellent path planning software has emerged in the market, and its application scenarios are more focused on furniture, construction, and mold fields.

IEMAI launched its own pellet printing solution three years ago. After continuous optimization and iteration, it has formed a product system that combines pellet extrusion system, pellet printer, robotic arm pellet 3D printing solution, and pellet raw materials. It has provided products or services to multiple well-known users at home and abroad. Currently, we are also working hard to create path software that is more suitable for pellet printing.

IEMAI Pellet Printing Solution

IEMAI Pellet Printing Exhibition Wall

IEMAI Pellet Printing Mold

02 High performance 3D printing, materials and software are indispensable

The hardware of the equipment is just the foundation, and users hope that the final product can achieve true high performance, which requires the coordination of materials and processes. IEMAI continues to invest in the modification testing of high-performance materials and has reached deep cooperation with globally renowned material manufacturers such as China Research Institute, Evonik and Victrex for joint testing, application promotion, and white paper release, providing global users with more suitable material solutions for additive manufacturing. At present, IEMAI has multiple cooperative PEEK, PEKK and PEAK materials available in the market, which can reduce crystallization rate, improve printability and longitudinal performance.

IEMAI High Performance Printing Solution

Secondly, the software process also has a significant impact on the printing results, and better path planning and program control have a positive effect on the printing surface effect, efficiency, and performance. At present, IEMAI has released two slicing software, IEMAI 3D Expert based on Cura and IEMAI 3D Slicer based on Orcaslicer; Motion algorithms optimized based on Marlin and Klipper, as well as control systems based on Linux, are gradually being used in the new generation of products; Remote file transmission and video streaming transmission based on P2P transmission protocol avoid the privacy embarrassment that user data must be kept on the server, and realize cloud control based on Internet and local control based on LAN; Based on visual algorithms, IEMAI is training its visual model to assist users in making judgments and handling special situations during printing.

IEMAI Software Series

03 Large format industrial 3D printing, high-speed continuous stable production is a necessary trend

At present, based on lightweight structural design and small-sized printing, almost all global consumer grade printer brands have achieved high-speed printing, greatly enhancing users’ confidence in 3D printing. In fact, 3D printing of larger parts requires higher speed and stable production, but larger equipment means heavier motion structures and longer motion distances, which increases the difficulty of achieving high-speed printing functions. IEMAI has accepted this challenge and the new NT series is equipped with a lighter IDEX dual head, a new control system and motion algorithm. The series will use the new slicing software IEMAI 3D Slicer and a better temperature control system, allowing various industrial materials to be printed at higher speeds and more stable during large-scale printing.

IEMAI large format printer

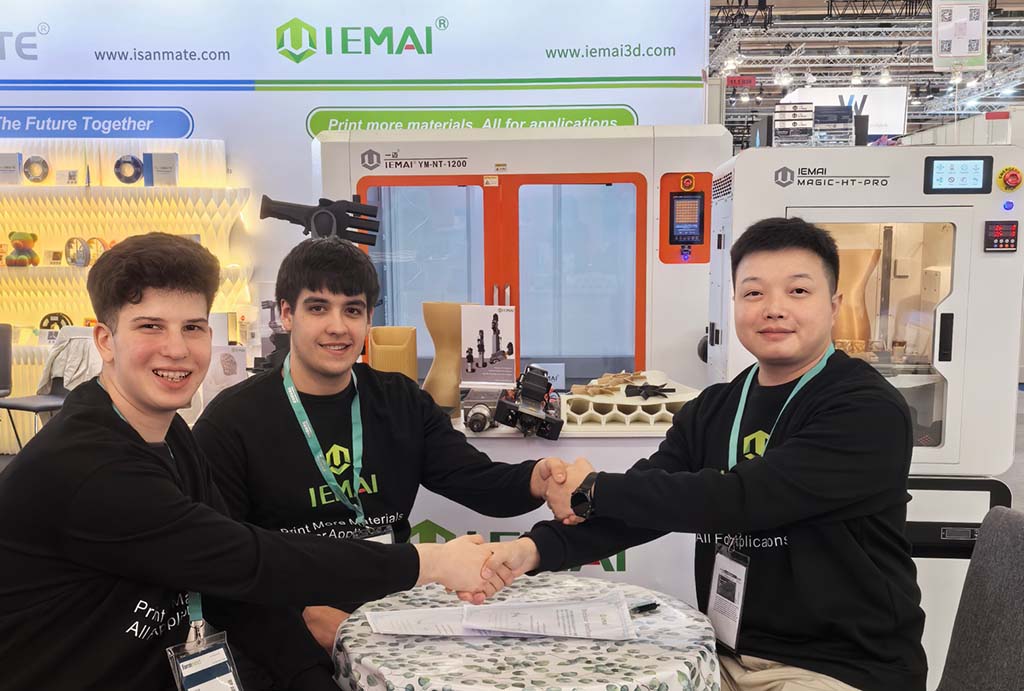

04 Signed Argentina Platinum Agency and continues to expand its global sales and service network

The Argentine agent has upgraded from gold grade to platinum, the French customer has shifted from end users to distributors and European local technical service providers, and more customers at Formnext have expressed their willingness to cooperate in distribution, which has further enhanced the international influence and service capabilities of the IEMAI3D brand.

Dongguan Imai Intelligent Technology Co., Ltd is a high-tech enterprise in China focusing on 3D printing R&D and production. Its brand IEMAI 3D is a global industrial grade 3D printer brand, committed to provide users with the “All-in-one” 3D printing solution of multi material compatible issue. IEMAI 3D supports most of the thermoplastic materials in the 3D printing markets and assist the user to resolve the issue encounter during manufacturing, and all 3D printers and materials have achieved CE AND ROHS certification. We attach great importance to brand building and have obtained trademarks certificates from China, United States and the European Union. We pursue core technology research and development, and have obtained software copyrights, invention patents, utility model patents, appearance design patents, and the title of national high-tech enterprise. At present, our 3D printing solutions have been applied to aerospace, automotive, petrochemical, medical and electronics manufacturing.