Project Description

The First Affiliated Hospital of Kunming Medical University is a large-scale general hospital integrating medical treatment, teaching, scientific research, and cadre health care. The hospital was built in 1941 and was originally named as “The affiliated Hospital of National Yunnan University School of University” (i.e. Yunda Hospital). In 1993, it was appraised by the Ministry of Heath as the first batch of “Tier-A hospitals”. At present. The number of beds in the hospital is 4000 (including 1000 in Chenggong) with 57 clinical and medical technical departments. There are 5 national key specialties, 24 provincial key clinical specialties, 16 provincial quality control centres, 30 internal research laboratories (8 research institutes), and 217 prefectures (Cities) and countries in Yunnan Province. The hospital has established a medical strategic alliance;

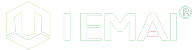

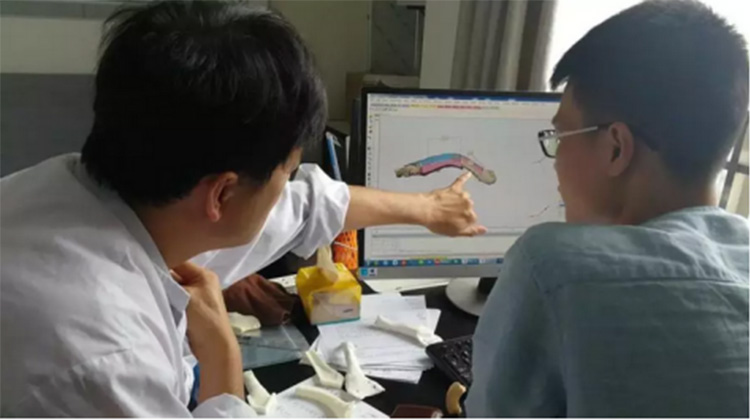

On July 3, 2018. Shi Yunfei, director of the Department of Thoracic Surgery of the First Affiliated Hospital of Kunming Medical University used a high-temperature 3D printer MAGIC-HT-L from IEMAI 3D to perform a 3D printed clavicle replacement operation. According to verification, this is the world’s first use of 3D printing technology to print the PEEK prothesis for collarbone replacement. The operation also solves other complicated problems of patients who also have multiple lesions, including vessel replacement, tumour resection, clavicle replacement and other types of operations.

3D printed PEEK implants have the advantages of individualization, precision, and closeness to autologous bone. There will be no barriers to metal materials in the later treatment of cancer patients, and it will not affect the patient’s CT and NMR, which is helpful for the patient’s chemotherapy afterwards and etcetera.

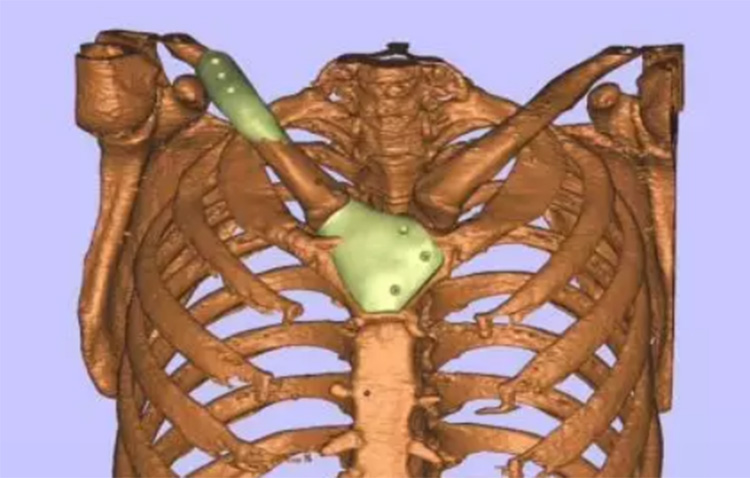

PEEK material was selected for the first operation. After repeated research by the combine work from doctors and engineers; with the help of CAD Software for modification, after many times of revisions and demonstration, the guide plate and clavicle model were finally finalized.

PEEK (polyetheretherketone) is a special polymer material with excellent properties such as safety stability, high temperature resistance, self-lubricating, easy processing, high mechanical strength and low dissolution. It can withstand repeated autoclaving and has been used several times in the field of medical. PEEK has an excellent compatibility with the human body, and its elastic modulus is similar to human bone. As an artificial bone material, it has gradually replaced the traditional titanium metal and is currently a good choice for substitution of bone.

Through 3D printing, a highly personalized, precise and customized prothesis is realized which brings a completely new treatment methods to patients and doctors. With the development of science and technology, it will play a revolutionary role in the clinical medicine. The role of IEMAI 3D high temperature 3D printer MAGIC-HT-L can achieve a layer resolution of 0.05 mm, position accuracy X/Y: 12.5μm and Z: 1.25μm. The machine is easy to maintain, PEEK material also meets the requirements of medical use, thus the First Affiliated Hospital of Kunming Medical University selects the machine and materials for clinical use.

↓↓Brand Introduction of IEMAI 3D↓↓

Imai Intelligent Technology Co. Ltd. is a high-tech enterprise in China focusing on 3D printing R&D and production. Its brand IEMAI 3D is a global industrial grade 3D printer brand, committed to provide users with the “All in one” 3D printing solution of multi material compatible issue. IEMAI 3D supports most of the thermoplastic materials in the 3D printing markets and assist the user to resolve the issue encounter during manufacturing, and all 3D printers and materials have contained CE and ROHS certification. We attach great importance to brand building and have obtained trademarks certificates from China, United Sates and the European Union. We pursue core technology research and development, and have obtained software copyrights, invention patents, utility model patents, appearance design patents, and the title of national high-tech enterprise. At present, our 3D printing solutions have been applied to aerospace, automotive, petrochemical, medical, dental and electronics manufacturing.

Project Details

- Application Field: Medical Implant

- Terminal: The First Affiliated Hospital Of Kunming Medical University

Printer & Material

- Printer Used: MAGIC-HT-L

- Material Used: PEEK