Project Description

In the traditional method, the designing of a prototype needs a long time to proceed such as designing, cutting, painting, testing and etcetera. These methods required skilled craft man to do, which is an expensive cost and wastage of materials is inevitable. With the help of 3D Printing Technology, designers will be able to design more complicated model and greatly reduce the wastage of materials.

“My design philosophy follows that design and manufacturing are inseparable. With the popularity of 3D printers, I can closely tie design and technology together. For example, in the design process, the scaled model data produced by a household-level 3D printer can be directly used in the physical manufacturing of the 3D printing factory to achieve perfect consistency between the design and the physical production.

Today, FDM can be said to be the lowest budget 3D Printing Technology. I used FDM as an entry point to discuss the changed that 3D printing has made to contemporary design and to prove that design and manufacturing are inseparable. For FDM technology, the filling and contour-like layer patterns hidden under the surface are its most representative features, but people regard it as rough defects. In my work “Infill Chari”, I present them positively and transform them into the unique visual language of FDM.” Said Zhang JianXiang

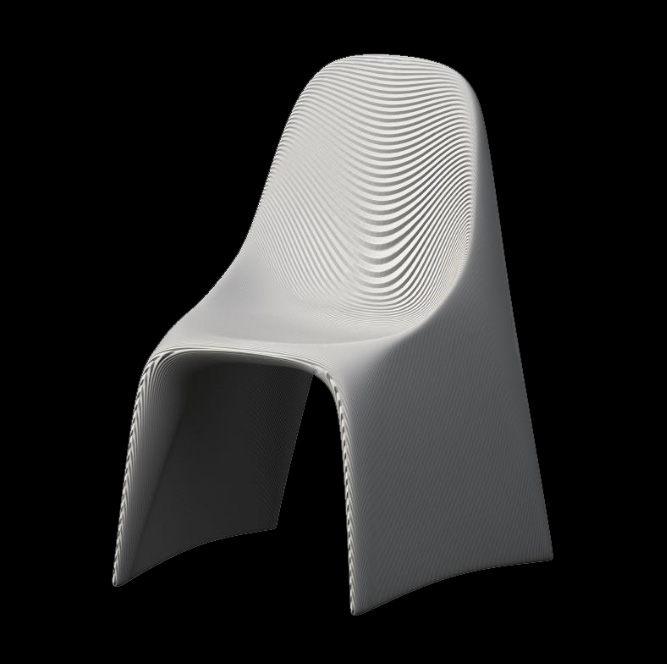

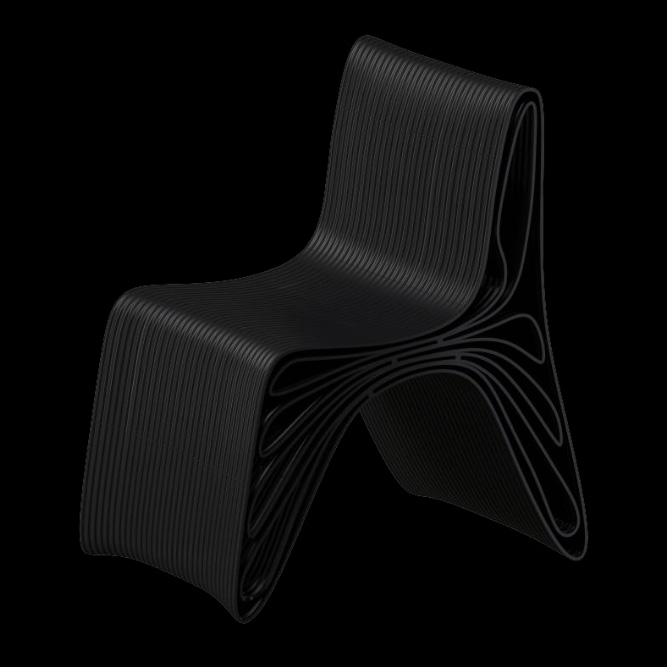

The three products unveiled on the exhibition are “Crown Chair”, “Infill Chair” and “Fold Chair”.

The Crown Chair is a work perfectly shows the unique contour pattern of FDM. I incorporated the layer pattern was originally consider a defect into the shape of the product itself. The sharp back line makes the texture of each layer more prominent.

Infill Chair is to show the internal filling of 3D Printing model. FDM technology will generate a net-like filling structure inside the model during printing. Coupled with the translucent properties of the PLA material, the inner filling can be seen through the outer wall of the finished product. However, this kind of filling is often regarded as a low degree of completion effect, thus I use design means to transform it into its unique visual language, so that it can be naturally integrated into the product.

Fold Chair is another attempt to extend FGF to FDM technology. FGF has faster printing speed and higher strength, which is very suitable for printing on larger furniture. In order to reflect the efficiency of this printing method, I designed the lines on its side to be freely stacked silk, as if making it is as simple and fast as stacking silk.

Polymaker: Promoting the development of 3D printing technology is inseparable from the support of materials. In order to facilitate the promotion and development of the application of super-large 3D printing technology, Polymaker has invested heavily in the development and testing of materials. After mastering the testing methods, accumulating rich experience and practical cases, the new 3D printing pellet product line PolyCore™ was officially launched.

IEMAI 3D: The era of digital customized furniture is coming. Among all 3D printing technologies, direct 3D printing of furniture from pellets is a lower cost, high efficiency, and environmentally friendly manufacturing method. IEMAI3D has been focusing on the application and promotion of FDM technology. This time, it has teamed up with Zhang JianXiang and Polymaker to launch 3D printed chairs, aiming to promote the development of digital manufacturing furniture and help the furniture industry with 3D printing technology.

Project Details

- Prototype: Furniture

- Terminal:Designer

Setup Used

- Printer Used: FAST-JET-780 & FAST-JET-1500

- Material Used:PETG, ASA