IEMAI 3D Printing Filaments

IEMAI 3D Printing Materials allows you to have an excellent printing experience; with our guidance in pre/pro-processing, you will obtain a detailed and good-surface finished print prototype.

Our 3D Printing Materials are independently developed and using our IEMAI 3D Printers, the filament will be able to outperform well and provide you with an amazing experience and performance for your parts or prototypes.

IEMAI 3D High-Performance Materials

IEMAI 3D High Performance 3D Printing Materials allow you to print industrial-grade parts and have superior-performance under ultra-lightweight conditions. These materials have excellent mechanical, thermal, electrical properties and also excellent biocompatibility compare to the ordinary polymer. For example, IEMAI 3D High-Performance materials PEEK has been used in medical field such as surgical guide-plate and prothesis.

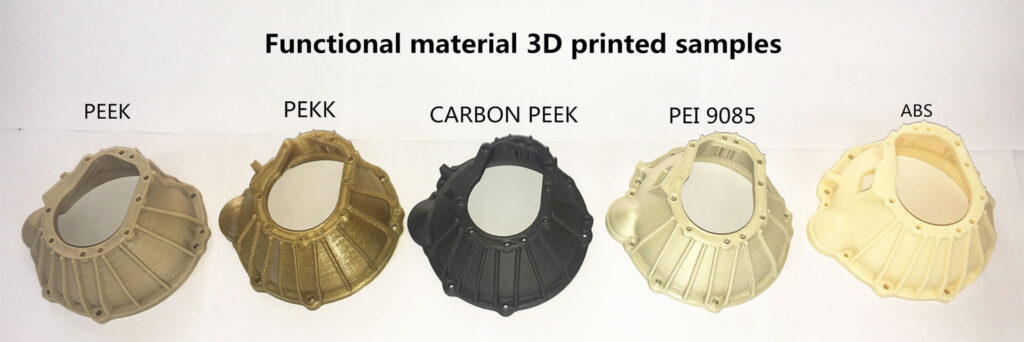

The figure on the right shows a set of samples of the same designed printed by IEMAI 3D High-Temperature Printer using different high-performance materials .

PEEK is considered as one of the world’s highest performing functional materials. It has excellent biocompatibility, chemical resistance, mechanical properties, and thermal properties. PEEK is a semicrystalline thermoplastic with excellent mechanical and chemical resistance properties that are retained to high temperatures. PEEK Medical Research, PEEK Medical Implant & PEEK Industrial are available options to serve different industries.

PEEK Medical Research & PEEK Medical Implant have excellent biocompatibility and close to bone modulus, which allow them to become a favorable medical material for sterilization-compatible devices and surgical implantations.

PEEK Industrial has superior mechanical properties. It is often used in demanding applications such as aerospace, automotive, and chemical industries.

PEKK is a semi crystalline thermoplastic from the PAEK family, commonly used in extreme operating environments. It has similar performance as PEEK which has excellent mechanical and chemical resistance properties that are retained to high temperatures, but relatively easier to print than PEEK due to its lower rate and degree of crystallinty.

It is often used in demanding applications such as aerospace, automotive and chemical industries.

PEI 9085 is a high performance material that have excellent thermal properties, exceptional dimensional stability, good chemical resistance, and inherent flame retardancy.

PEI 9085 has natural (unpigmented) colors and it is widely used in application such as medical, electrical/electronic, automotive, and aerospace industries.

PEI 1010 is an amorphous polymer that have excellent thermal properties, exceptional dimensional stability, good chemical resistance, and inherent flame retardancy. As the glass transition temperature can reach up to 217°C, which allows PEI 1010 to print parts with excellent property.

PEI 1010 has a translucent colour of amber and it is widely used in application such as medical, electrical/electronic, automotive, and aerospace industries.

PPSU is a type of high temperature aromatic sulfone polymer. For a long time, it has been considered as one of the most excellent composite polymers in plastic field. PPSU can be used under a high temperature of 180˚C, PPSU has an excellent hydrolysis resistance and able to resist common acid and bases over a broad temperature range.

PPSU also offers superior high heat deflection temperature, able to withstand repeated steam sterilization, good electrical properties, and resistance to environmental stress cracking.

PPS is a high-performance polymer that exhibits exceptional chemical resistance along with high thermal and mechanical properties. Widely known as one of the most chemically resistant thermoplastic materials available. PPS is completely insoluble in any known solvent under 200°C.

PPS is used in some of the most demanding applications in Auto, Chemical Processing, Oil & Gas, and Electronics. It is inherently flame retardant and self extinguishing, making it an ideal material for electrical/electronics applications.

CF-PEEK is a composite polymer, black in colour. It has excellent biocompatibility, chemical resistance, mechanical properties, and thermal properties.

It is considered as one of the world’s highest performing functional materials, which allow it to use in harsh environment. CF-PEEK is produced using 10% carbon fiber content and still having all the advantages of PEEK. At the same time, it is lighter than PEEK, having better interlayer adhesion and better temperature resistance.

At present, it often used in demanding applications such as aerospace, automotive, and electrical industries.

GF-PEEK is a composite polymer, grey in colour. It has excellent biocompatibility, chemical resistance, mechanical properties, and thermal properties.

It is considered as one of the world’s highest performing functional materials, which allow it to use in harsh environment. GF-PEEK is produced using 10% glass fiber content and still having all the advantages of PEEK. At the same time, it is lighter than PEEK, having better interlayer adhesion and better temperature resistance.

At present, it often used in demanding applications such as aerospace, automotive, and electrical industries.

CF-PPS is a composite polymer, black in colour. It has excellent chemical resistance, mechanical properties, and thermal properties.

It is considered as one of the world’s highest performing functional materials, which allow it to use in harsh environment. CF-PPS still having all the advantages of PPS. At the same time, it is lighter than PPS, having better strength, stiffness and temperature resistance.

At present, it is often used in demanding applications such as aerospace, automotive, and electrical industries.

CF-PPA is a composite polymer, black in colour. It has excellent chemical resistance, mechanical properties, and thermal properties.

It is considered as one of the world’s highest performing functional materials, which allow it to use in humid or high temperature environment. CF-PPA still having all the advantages of PPA. At the same time, it is lighter than PPA, having better strength, stiffness and temperature resistance.

At present, it is often used for engineering applications from mechanical prototypes to automotive components.

CF-PA12 is a carbon fiber reinforced PA12 filament. The carbon fiber reinforcement provides significantly improved stiffness, strength, and heat resistance with outstanding layer adhesion. Under high temeprature up to 120˚C, it still able to maintain the same mechanical properties.

CF-PA12 is lighter than PA12 and maintain the same advantages.

GF-PA12 is a glass fiber reinforced Nylon 12 filament. With the same specification as the orginal PA12, the material also exhibits more excellent thermal and mechanical properties without sacrificing the layer adhesion. IEMAI 3D has used it in various cases such as boxes and structural component of unmanned aircraft.

CF-PA6 is a carbon fiber reinforced PA6 filament. The carbon fiber reinforcement provides significantly improved stiffness, strength, and temperature resistance with outstanding layer adhesion and low warpage.

CF-PA6 is lighter than PA6 and maintain the same advantages.

CF-PC is reinforced with the carbon fiber, that features a very high strength to weight ratio. The thermal resistance of is one of the highest among the 3D printing filaments and also having excellent mechanical properties. It is the ideal choice for a wide range of engineering application.

CF-ABS is an improved carbon fiber reinforced filament. Compare to the normal ABS, it is an ideal choice for user that wants a part with high modulus, excellent surface quality, dimension stability and lightweight. Compare with the normal ABS, CF-ABS reduces the coefficient of thermal expansion, this reduces the wraping happens when printing and higer power distribution of mechanical stress.

CF-ASA is an improved carbon fiber reinforced filament. Compare to the normal ASA, it is an ideal choice for user that wants a part with stiffness, dimension stability and lightweight. At the same time, it maintains the same advantages of ASA such as weather and UV resistances.

CF-PETG is an improved carbon fiber reinforced PETG filament. The carbon fiber reinforcement provides significantly stiffness and strength with low warpage. CF-PETG is lighter than PETG and maintain the same advantages.

CF-PLA is an improved carbon fiber reinforced PLA filament. The carbon fiber reinforcement provides significantly hardness and bending modulus while still retaining the ease printing and dimensional stability of normal PLA.

ESD-ABS is a modified materials of ABS and carbon nanotubes with a surface resistivity of 10^5 Ω – 10^9 Ω. Commonly used by varies industry to make protective housings, support brackets and assembly tools for electronic components, which are very sensitive to electrostatic electricity discharges.

PA12 filament is based on a copolymer of Nylon12. It is a semi-crystalline thermoplastic with low density but with high thermal stability.The filament has excellent strength, toughness, and heat resistance of up to 180˚C.

PA12 is commonly applied in industry as it has good tenacity and cushioning at low temeprature and high impact resistance.

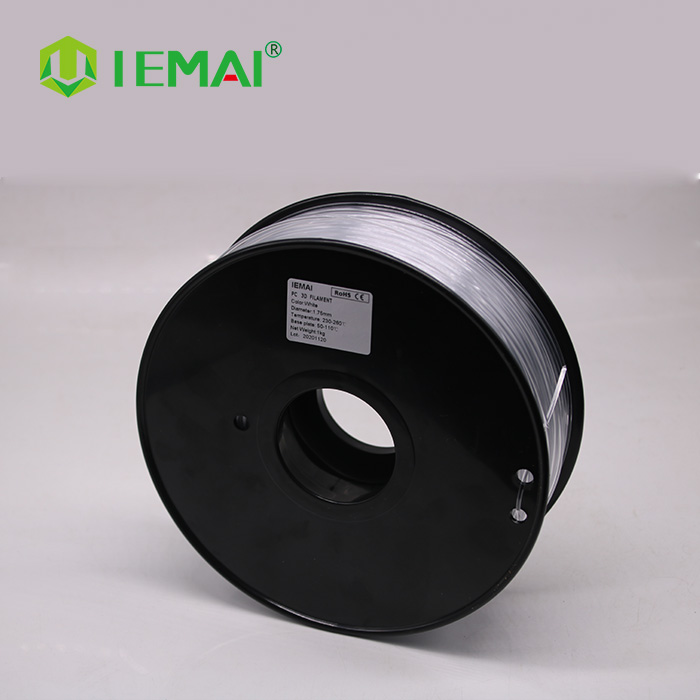

PC is a type of high molecular polymer containing carbonate groups in the molecular chain. PC is an excellent high temperature 3D printing material, which contain excellent mechanical property and heat resistance . IEMAI 3D’s PC can use for printing functional prototypes and parts, which has excellent details and surface quality and make it the ideal choice for a wide range of engineering applications

It also has good wear resistance, good self-lubrication, high toughness, good melt fluidity, precise printing accuracy, smooth appearance, and natural gloss. As most of the PC has high shrinkage, IEMAI 3D manage to reduce its shrinkage and allow it to print easily.

Acrylonitrile-Butadiene-Styrene (ABS) is a thermoplastic polymer material which have high strength, high rigidity and easy to process. Due to its strong physical characteristic, thermal resistance, and chemical resistance, it is commonly used as the plastic shell for apparatus. However, ABS will have its mechanical strength weaker and discoloration after exposed to weather conditions (UV light, oxygen, moisture, heat) because Polybutadiene stimulate the oxidation of Polystyrene. UV stabilizer can be introduced to improve this.

ABS is widely used in mechanical, automotive, electronic, textile, and construction industries, which is a versatile engineering thermoplastic.

ASA is an alternative to ABS with an improved weather resistance. Its UV resistance and excellent mechanical properties make it the perfect choice for real life applications. ASA has lower glass transition temperature than ABS.

It is commonly used for outdoor appliance or outside parts of vehicles.

Polyethylene Terephthalate Glycol-modified (PETG) is a tough and durable materials and it is easy to use. The strength of it allow to be a suitable material for food packaging, the chemical non-reactive characteristic allow it to be the most valuable material in medical field, normally used for orthopedic and prosthetic device.

PETG is a very waterproof material which make it become an excellent choice for outdoor activity. It also has excellent chemical resistance, which can be well-used in both acidic and alkaline environment, PETG also have strong impact resistance, which make it be the substitute material for PMMA and PC.

Polypropylene (PP) is a durable, high toughness and exceptional fatigue resistance. It has good resistance in chemical, thermal and electrical. It is one of the commonly used plastic on earth such as electrical components and prototyping.

It is commonly applied in field such as functional prototypes, guides, sleeves, and protective cases.

Thermoplastic polyurethane (TPU) is a soft material which contain both feature of rubber and plastic. It is a semi-flexible and chemical resistance filament with strong interlayer bonding. It also has good corrosion resistance to industrials oils and chemicals.

It is commonly applied in field such as functional prototypes, guides, sleeves, and protective cases.

Polylactic Acid (PLA) is a plastic extract from starch (commonly from corn) which is low environmental impact. It is a derivative of starch, green and renewable, a biodegradable material (degrade by itself in the soil), which is environmentally friendly.

It is commonly used for decoration and asethetic purposes. This material is cheap and easy to print thus it is the most suitable filament for beignners to use for their very first 3D printes.

Why Choose Our Filament

We provide the 3D Printing Filament in the most afforable price.

All 3D Printing Filament is developed by ourself and have obtained CE and RoHS Certification.

We also partner with different material companies to produce the higest quality materials for the users.

We provide the specification for each materials, thus you will not take much effort to figure out what is the most suitable parameters for that certain materials and start your print soon.