Project Description

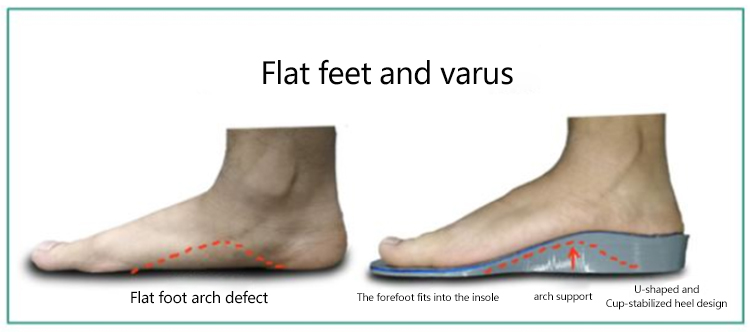

When walking or standing, the arch of the foot sinks, the legs are prone to fatigue and itching, which can cause other sequelae in the long run

Customized insoles can re-adjust the arrangement of the bones of the feet by adjusting the improper negative force points of the footsteps, so that the bones can be arranged to the best condition for a long time

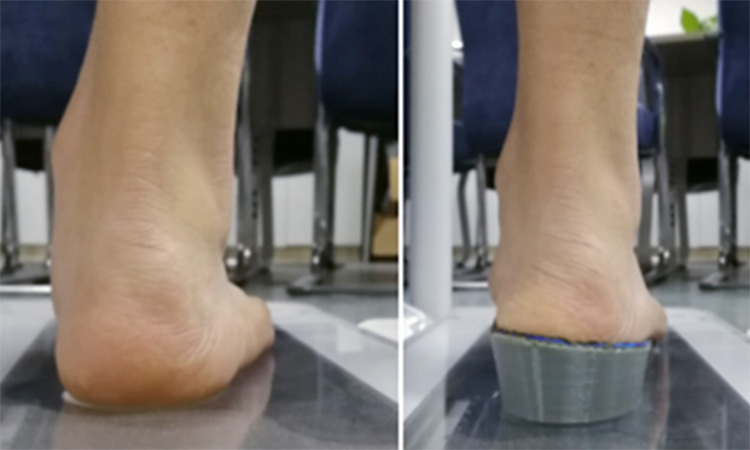

The user in the example has been tortured by flat feet and internal and external turning for a long time, but there is no good solution. Other customized solutions will incur very high costs.

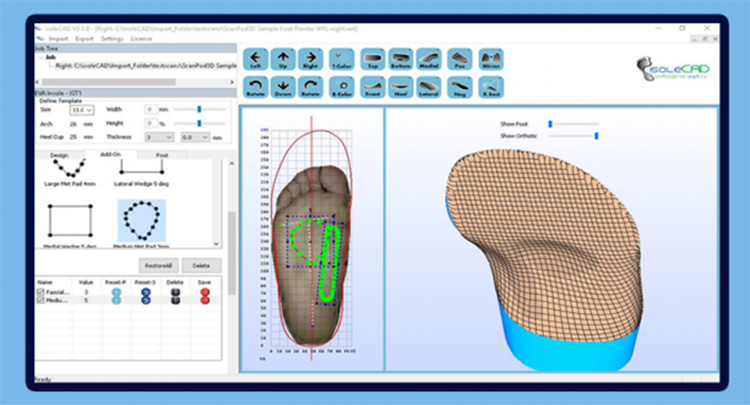

Through 3D scanning, we can obtain the data at the shortest tine, and through software and opinions from the physician, we can model out the suitable digital model of insoles for rehabilitation.

When all the digital files were prepared, we customized the TPU insoles for the customers through the 3D printer (MAGIC-HT-PRO from IEMAI 3D). Not only did we complete the customization is a very short period, but also left a large amount of cost for the user. This is the advantage of 3D Printing Technology.

The 3D printer MAGIC-HT-PRO has a large size of 31 cm * 31 cm *48 cm which can meet the printing customization of most insole sizes, but also can support the printing of flexible materials TPU and TPE due to the present of compact near-end 3D printing head.

↓↓Brand Introduction of IEMAI 3D↓↓

Imai Intelligent Technology Co. Ltd. is a high-tech enterprise in China focusing on 3D printing R&D and production. Its brand IEMAI 3D is a global industrial grade 3D printer brand, committed to provide users with the “All in one” 3D printing solution of multi material compatible issue. IEMAI 3D supports most of the thermoplastic materials in the 3D printing markets and assist the user to resolve the issue encounter during manufacturing, and all 3D printers and materials have contained CE and ROHS certification. We attach great importance to brand building and have obtained trademarks certificates from China, United Sates and the European Union. We pursue core technology research and development, and have obtained software copyrights, invention patents, utility model patents, appearance design patents, and the title of national high-tech enterprise. At present, our 3D printing solutions have been applied to aerospace, automotive, petrochemical, medical, dental and electronics manufacturing.

Project Details

- Application Field: Customized orthopedic insole

- Terminal: Individual User

- Total Cost: $80

- Time Spend: 4 Hours

Printer & Material

- Printer Used: MAGIC-HT-PRO

- Material Used: TPU