At the German Formnext exhibition in 2023, more than 800 3D printing companies from around the world participated in the exhibition. As the world’s leading professional additive manufacturing exhibition, Formnext has always been the direction indicator for the development of additive manufacturing technology. Users can see the latest of 3D printing technology solutions and products from all over the world at the exhibition.

At this exhibition, IEMAI3D demonstrated its latest integrated additive and subtraction manufacturing and high-temperature 3D printing solutions. IEMAI’s professional and technical achievements attracted the attention of many customers and received a large number of inquiries and orders. Some customers even signed agency agreements on-site.

- High-temperature 3D printing solution that combines additive manufacturing and CNC milling

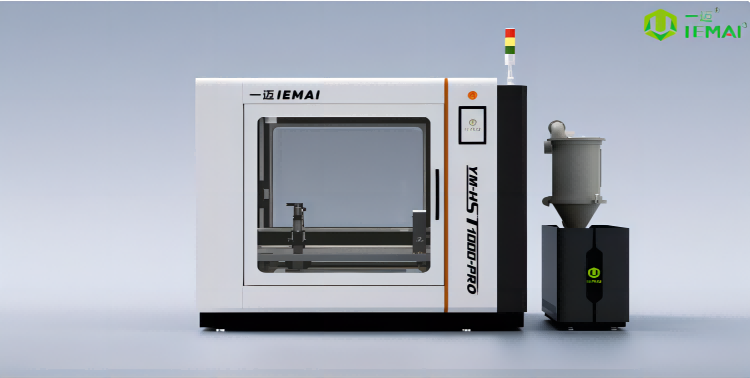

YM-HST-1000-PRO has the characteristics of high temperature, high speed, large format printing combines additive manufacturing and CNC milling.

When it is used as a filament 3D printer, its printing temperature can reach 450°C, the hot bed temperature can reach 120°C, and the cavity and material box temperature can reach 70°C. IDEX print head mode, built-in acceleration sensor, Klipper Firmware development , max print speed 400mm/s, max print volume 1000×1000×1000mm. It adopts a vacuum adsorption platform design that eliminates the need for glue application and rapid mold removal. New logic automatic leveling ,effectively compensates for platform errors.

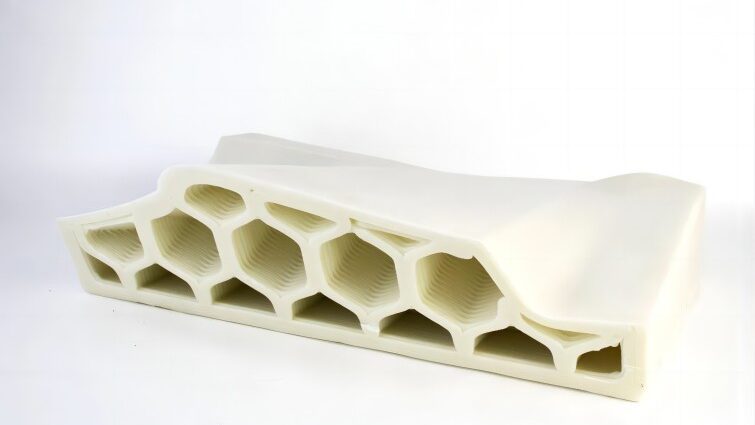

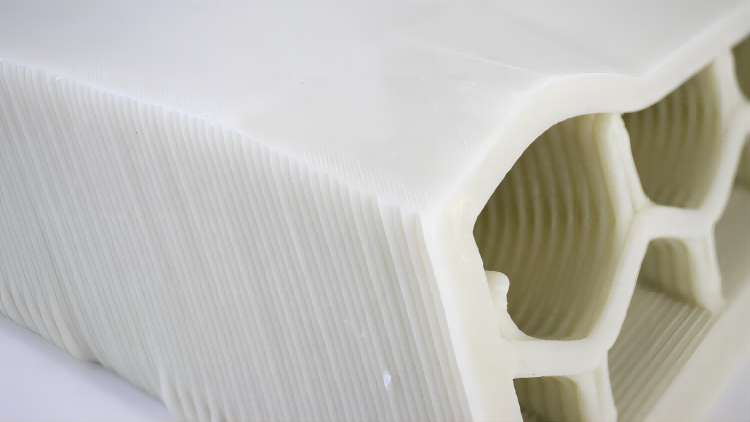

3D printer as a combined additive manufacturing and CNC milling, it can provide pellet printing throughput of 3KG/H, a printing temperature of up to 450°C, and supports layer-by-layer printing/layer-by-layer CNC milling and overall printing/overall milling modes. It is suitable for Production of small and medium-sized composite molds.

The printing temperature of MAGIC-HT-PRO can reach 500°C, the hot bed temperature can reach 200°C, and the chamber temperature can reach 120°C, which provides excellent temperature conditions for printing high-performance materials. MAGIC-HT-PRO has a medium and large build size, reaching 310*310*410mm, with independent lifting dual print heads, filament absent warning, power failure recovery and automatic leveling, etc.,provides functional guarantee for printing high-performance materials.

- High performance series materials

In August 2023, IEMAI and VICTREX jointly released a white paper on PEAK material 3D printing optimized for additive manufacturing, and the two parties officially reached a global partnership in the field of high-performance material 3D printing. At this Formnext, IEMAI displayed VICTREX AM™200 Fil and its printed samples so that users can better understand its properties such as high wear resistance, high temperature resistance, fatigue resistance and corrosion resistance. As an optimized PEAK filament, VICTREX AM™200 Fil has the characteristics of slower crystallization, lower melting point, excellent ease of printing, and higher interlayer bonding force of printed parts.

In addition, IEMAI showcased a series of high-performance 3D printing materials at Formnext. These materials all have excellent mechanical properties/high and low temperature resistance/chemical corrosion resistance, as well as functional properties that bring great value to users, such as flame retardant/ Biological implantation/sterility/anti-static/lightweight, etc. IEMAI high-temperature series 3D printing materials all use metal trays to facilitate users to bake and dry at higher temperatures to achieve better printing results. In the future, IEMAI will continue to increase investment in research and development to meet the needs of global customers with better products and services.

Dongguan Imai Intelligent Technology Co., Ltd is a high-tech enterprise in China focusing on 3D printing R&D and production. Its brand IEMAI 3D is a global industrial grade 3D printer brand, committed to provide users with the “All in one” 3D printing solution of multi material compatible issue. IEMAI 3D supports most of the thermoplastic materials in the 3D printing markets and assist the user to resolve the issue encounter during manufacturing, and all 3D printers and materials have achieved CE and ROHS certification. We attach great importance to brand building and have obtained trademarks certificates from China, United Sates and the European Union. We pursue core technology research and development, and have obtained software copyrights, invention patents, utility model patents, appearance design patents, and the title of national high-tech enterprise. At present, our 3D printing solutions have been applied to aerospace, automotive, petrochemical, medical and electronics manufacturing.